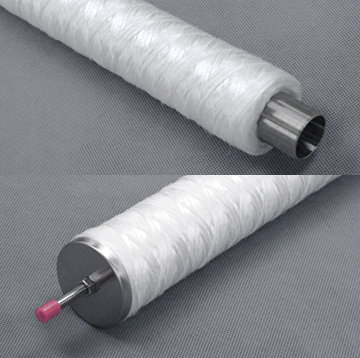

RTM Series High Flow Filter Cartridges

eHF Series High Flow Filter Cartridges

eHFM Series High Flow Filter Cartridges

Power Generation

Hydraulics & Lubrication

Electronics

Water Processing

Chemicals

Food & Beverage

BioPharma

Industrial Machinery

Ink Jet Printing

Use:Fossil and Nuclear Condensate Filtration, Back Flush Resin Pre-Coating System.

Content:

CondenPURE-S filter elements are used for conventional back flush resin pre-coating system to remove ionic contaminants and iron oxides from condensate.o Filter elements are made by stainless steel core and the yarn is wound onto the core in a precise repetitive pattern and use continuous strands of fibers that will not pull apart during back flush.

o The stainless steel core is cleaned, pickled, passivated and rinsed with de-mineralized water.

o Use continuous filament yarn for added durability.

o No fiber deterioration or migration.

o PP filament yarn is thoroughly washed by pure water to remove all lubricants, soaps and other residues and inspected and subjected to a foam test to insure that it is clean

o Superior high temperature resistance.

o ISO9001, ISO14001 and OHSAS18001.

Specification

Parameter

Ordering Information

| Filter Media | Continuous filament PP yarn media (Surface area : 0.28m^2 each) |

| Support | Stainless Steel 304 inner core |

| Connection | 1-3/16” (-24) external thread; Top screw bolt 1/4 ”-20 |

| Diameter | 2” (Approx. 51mm) |

| Length | 60” and 70” |

| Removal Rating |

5μm |

o Max. operating temperature : 80℃.

o Max. differential pressure : 3bar @ 65℃.

o Recommended flow rate : 3m^3/h each

Air-Water Back flush Strength:

Compressed air: 2.0 ~ 3.0m^3/h, Water: 4.5~6.5 L/min.

Pressure for each filter element: 1.5 ~ 2.0bar.